Provide you with the latest enterprise and industry news.

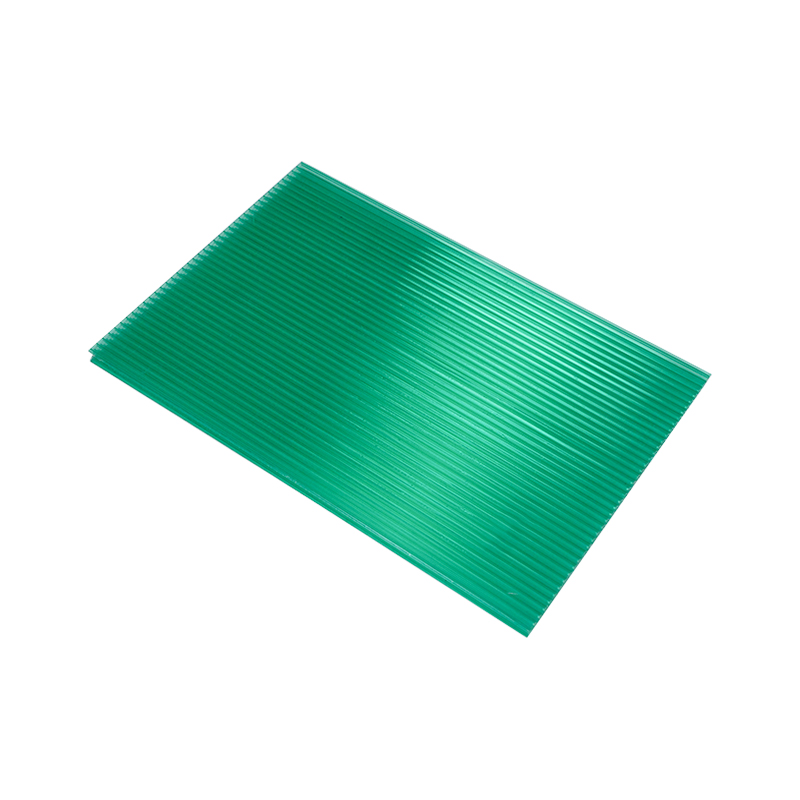

The methods for achieving high load-bearing capacity in polycarbonate hollow sheets can mainly be summarized as follows:

Structural Design Optimization

Multilayer Hollow Structure: polycarbonate hollow sheets typically adopt a multilayer hollow design, which effectively distributes the load and enhances the overall load-bearing capacity.

Reinforcements and Enlarged Edges: By adding reinforcing ribs and widening the edges or stressed areas during structural design, the load-bearing capacity and seismic performance of the sheets can be significantly improved.

Material Properties

High Strength and Toughness: The polycarbonate material itself has high strength and toughness, making the hollow-core sheets less likely to deform or break under load.

Impact Resistance and Weather Durability: Compared to traditional materials like glass, polycarbonate sheets have higher impact resistance and weather durability, maintaining stable performance in harsh environments.

Optimized Arrangement

Strategic Placement of Ribs: A reasonable arrangement of transverse and longitudinal ribs can reduce stress concentration areas, thereby improving the overall load-bearing performance.

Resistance to External Loads: By optimizing the layout, polycarbonate hollow sheets can better resist external loads, maintaining structural stability and safety.

Increased Elasticity

Incorporating Elastic Materials: During the design process, incorporating appropriate elastic materials can enhance the toughness of the structure and increase its seismic resistance.

Energy Absorption: The addition of elastic materials allows polycarbonate hollow sheets to absorb energy through deformation when impacted or subjected to vibrations, reducing structural damage.

Thickness and Dimensions

Key Factors: The thickness and dimensions of polycarbonate hollow sheets are crucial factors affecting their load-bearing capacity. Increasing the thickness and dimensions appropriately can improve their bending resistance and load-bearing capacity. However, it is essential to balance this with considerations of cost and weight in the design.

Manufacturing Process

Precision and Quality Control: The precision of the manufacturing process also affects the load-bearing capacity of polycarbonate hollow sheets. Advanced production techniques and quality control measures ensure the sheets' accuracy and performance meet design requirements, thereby enhancing their load-bearing capacity.

Achieving high load-bearing capacity in polycarbonate hollow sheets requires comprehensive consideration of structural design, material properties, arrangement, increased elasticity, thickness and dimensions, and the manufacturing process. These measures work together to ensure that polycarbonate hollow sheets can maintain stable performance under load and have good seismic resistance.